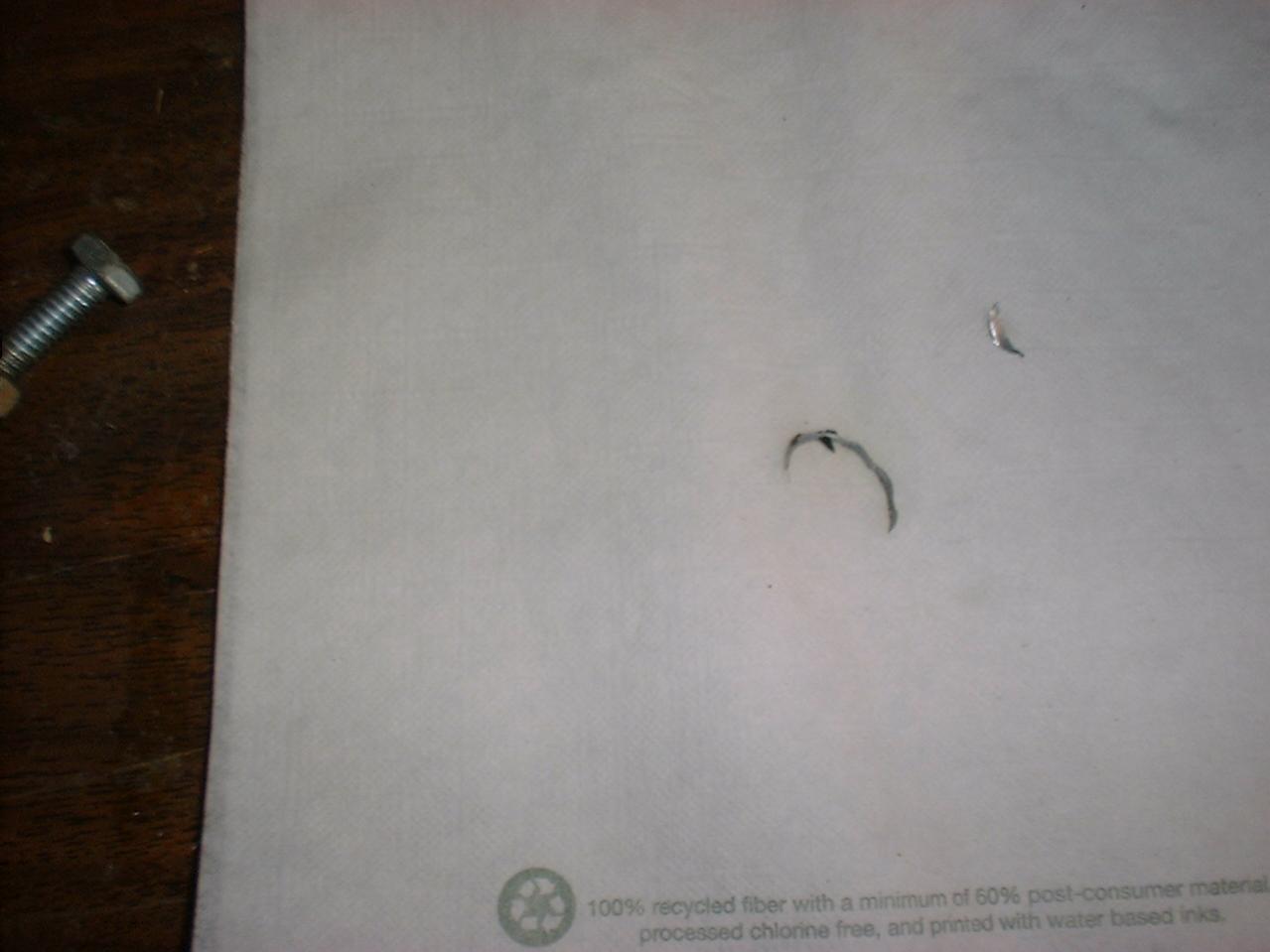

We’ve begun the recovery process. If you haven’t read the incident report, check that out here. In the first picture you’ll notice that the failed line was not simply under-flared. There were two largish sections of the flare that had fractured off and were still in the nut. I’m not completely sure what this tells me, certainly the there could have been too much flare pressure used, making the flare too thin. The factory tells me that they have seen failures like this when the nut is over-tightened. That is also possible, because we had been getting some weeping from this line and just snugged it down tighter. In any event, with the high pressure (the factory also tells me that some folks are foregoing the 3003 for some 5xxx series tubing) and the vibration, I’ve elected to go with hose from Aero based on the recommendation of Gene at Magnum. Incident Repair II

Pieces of the fractured flare removed from nut

To recap the damage, the pencil line shows the approximate delamination line. The factory-recommended technique works pretty well, just to take a quarter or bolt and tap lightly on the skin. If it’s good, it will make a reassuring thud sound, if it is delaminated it’ll sound like an egg shell being cracked to make scrambled eggs. Yea, I know, not a good sound. But, net, we were taking the foam back to the spar based on the factory’s recommendation anyway, to this was mainly in play side-to-side (the aft delamination stopped abruptly at the spar anyway). So, the factory recommended taking out the damaged foam and skin, then removing the paint within about 2″ of the damaged area, feathering it slightly. Then do the following layups, and maybe feather these slightly to make the following fill work easier. First we’ll do 2 layers of Unidirectional cloth at right angles, 45 degrees from the span, and then 1 or 2 layers lengthwise down the span of the wing. This area of the wing is not structural, they just want enough cloth there that the surface isn’t damaged by folks leaning on it or whatever.

Wing damage from reflector pole |

|

We have worked the top skin off carefully here, and have started to sand down to the spar. Note that the bulk of the foam is in good shape, it was just skin delamination. Also note the wires in the gapping hole. These are the coax to the winglet com antenna and the 3 sets of wires to damaged stobe light. All of these wires were fine, thankfully, so we just carefully worked around them, and then sawed the foam out with a hacksaw.

Delaminated skin removed |

|

Damaged foam core removed |

Posted By: Brett FerrellSunday November 9th, 2008 at 10:03 PM

Categories: Incident Repairs Tags: Building Incident Repairs

[…] The road to recovery has begun in earnest. I’m still splitting time between Victor Fox and the basement, but I have decided to go with the GRT EIS engine pod. That will keep me from having to run all of the engine instrument wires back up the electrical conduit after pulling the oil lines outs. To that end, I have pulled all of those instruments out of the Blue Mountain EFIS/1, and pulled the wire back to the cowling, and pulled the hard-tubed (3003) aluminum oil lines out as well, and cleaned up the oil in the nose and cabin. The panel and all of the seats are out, so we’re in a good position to make our repairs. I have 2 new oil lines on order, made from SS braided hose, and I’ve decided not to put any valves in up front. It just ended up being too complicated, so both nose oil coolers will always be in the loop. If the oil gets too cold in the winter, I’ll just block the inlet air from the fresh air cooler, and if the nose is too hot in the summer, I’ll ventilate the nose. Also, Jerry and Bob kindly helped me get the damaged copilot wing to Jerry’s shop, and all of the delaminated skin and damaged foam has been removed back to the spar, and Velocity is making a custom forward wing foam block to replace it with (they wanted it to be one chunk of foam – thanks guys!). So most of the thinking and decision-making is done, and now I’m mostly waiting for the parts. Check out the repairs page. […]

[…] Ah, our first update of the new year. Well, we’re still making steady progress, but I was really lazy over the holidays (we got a Wii, and I really took a stress relief break). See, I’m taking a new role at work, returning to engineering from my 9 year IT hiatus, and the decision to change back took a toll on me. But, enough of that, we are making progress, doing final finishing work on the wingtip, fairing the wing repair, and getting the rudder cable delamination laid up. Jerry has pretty much talked me into finishing the whole wing and removing and reapplying primer and some actual paint. The primer took a real beating last year, and he’s right, it ought to be covered. The factory recommended Dupont primer and paint (Nason urethane primer and topcoat, select primer 421-17 color buff and ful-thane 2k snow white top coat), and that’s likely what we will use. Check out the progress here. […]

[…] It’s about time for an update. My new job is causing me to work more than I would like, and spend somewhat less time working on the plane than is typical, but we have been working away the whole time. We’ve just finished up the fill-and-finish work on the damaged copilot wing area, and are cleaning up the aileron pocket and bolt hole recess. We should be spraying primer on it soon, and, as it’s been warm this weekend, we’re doing work at the hangar as well. Today we put in the new oil hoses to replace the kit tubing which failed. I’m really happy with how this turned out. We’re looking forward to priming the wing and swapping it out with the pilot side and getting it fixed up (and hopefully the canard too) before spring hits. Then we can focus on some finishing work on the fuselage and prime it, then paint everything. I bought the factory-recommended Nason grey primer and snow white top coat, so she should be looking sweet when we next take to the skies. Check out the progress here. […]